Building Greener Tomorrow

Sustainable engineering practices are becoming increasingly important in today’s world. With the growing concern for the environment, it is essential to create environmentally friendly and efficient solutions for a more sustainable future. In this blog post, we will discuss the importance of sustainable engineering practices and their role in building a greener tomorrow.

Sustainable Engineering

Sustainable engineering is the practice of designing, building, and operating systems, structures, and processes that minimize environmental impact, conserve natural resources, and promote social well-being. It involves the use of eco-friendly design, green building practices, and sustainable construction techniques to create sustainable solutions.

Sustainable engineering practices are essential for building a greener tomorrow. They involve the use of eco-friendly design, green building practices, and sustainable construction techniques to create sustainable solutions. Environmental Engineer Emma can find green building certifications, sustainable materials databases, environmental impact assessment tools, and sustainability conferences to help her stay up-to-date with the latest sustainable engineering practices. By reducing environmental impact through design, staying compliant with green building standards, and creating eco-friendly solutions, we can build a more sustainable future.

Eco-Friendly Design

Eco-friendly design is an essential aspect of sustainable engineering. It involves designing products, systems, and processes that minimize environmental impact and promote sustainability. Eco-friendly design can be achieved by using sustainable materials, reducing waste, and minimizing energy consumption.

Eco-friendly design is an essential aspect of sustainable engineering. It involves designing products, systems, and processes that minimize environmental impact and promote sustainability. Eco-friendly design can be achieved by using sustainable materials, reducing waste, and minimizing energy consumption. One of the most significant benefits of eco-friendly design is that it can help reduce the carbon footprint of a product or process. By reducing the amount of energy required to produce a product or service, we can reduce the amount of greenhouse gases emitted into the atmosphere.

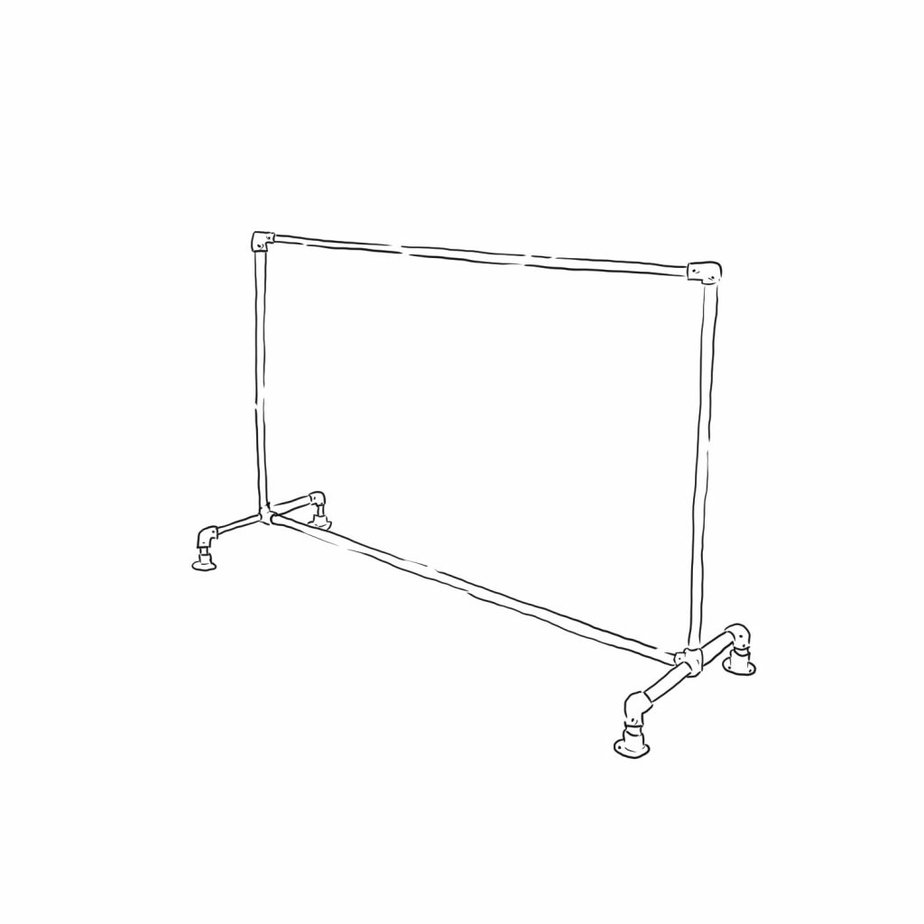

Build Your Eco-Friendly Solution with Kee Klamp

Are you looking for a way to build your own eco-friendly design projects? Whether you want to create a green house, a solar panel, or a compost bin, you can do it with the help of Kee Klamp fittings.

Learn MoreGreen Building Practices

Green building practices are another critical aspect of sustainable engineering. They involve the use of sustainable construction techniques to create environmentally friendly buildings. Green building practices can include the use of sustainable materials, energy-efficient lighting and HVAC systems, and water conservation techniques.

Green building practices are another critical aspect of sustainable engineering. They involve the use of sustainable construction techniques to create environmentally friendly buildings. Green building practices can include the use of sustainable materials, energy-efficient lighting and HVAC systems, and water conservation techniques. One of the most significant benefits of green building practices is that they can help reduce the environmental impact of buildings. By using sustainable materials and energy-efficient systems, we can reduce the amount of energy required to operate a building and minimize the amount of waste generated.

Environmental Engineering

Environmental engineering is a branch of engineering that focuses on the protection of the environment and public health. It involves the use of engineering principles to design and implement solutions that minimize environmental impact and promote sustainability. Environmental engineering can include the use of environmental impact assessment tools, sustainable materials databases, and green building certifications.

Environmental engineering is a branch of engineering that focuses on the protection of the environment and public health. It involves the use of engineering principles to design and implement solutions that minimize environmental impact and promote sustainability. Environmental engineering can include the use of environmental impact assessment tools, sustainable materials databases, and green building certifications. One of the most significant benefits of environmental engineering is that it can help reduce the environmental impact of industrial processes. By designing and implementing sustainable solutions, we can minimize the amount of waste generated and reduce the amount of energy required to operate industrial processes.

Sustainable Construction

Sustainable construction is the practice of designing and building structures that minimize environmental impact and promote sustainability. It involves the use of sustainable materials, energy-efficient systems, and green building practices to create environmentally friendly buildings. Sustainable construction can help reduce the environmental impact of construction projects and promote sustainability.

Sustainable construction is the practice of designing and building structures that minimize environmental impact and promote sustainability. It involves the use of sustainable materials, energy-efficient systems, and green building practices to create environmentally friendly buildings. Sustainable construction can help reduce the environmental impact of construction projects and promote sustainability. One of the most significant benefits of sustainable construction is that it can help reduce the amount of waste generated during construction projects. By using sustainable materials and green building practices, we can minimize the amount of waste generated and reduce the environmental impact of construction projects.

Conclusion

Sustainable engineering practices are essential for building a greener tomorrow. They involve the use of eco-friendly design, green building practices, and sustainable construction techniques to create sustainable solutions. Environmental Engineer Emma can find green building certifications, sustainable materials databases, environmental impact assessment tools, and sustainability conferences to help her stay up-to-date with the latest sustainable engineering practices. By reducing environmental impact through design, staying compliant with green building standards, and creating eco-friendly solutions, we can build a more sustainable future.

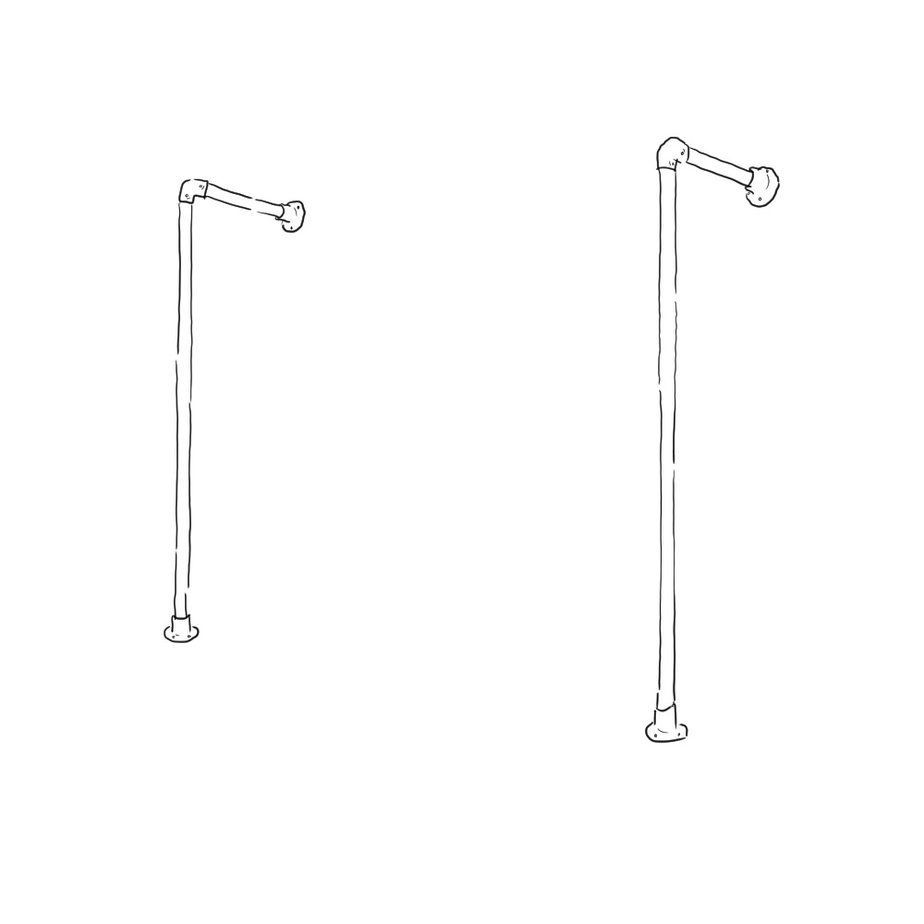

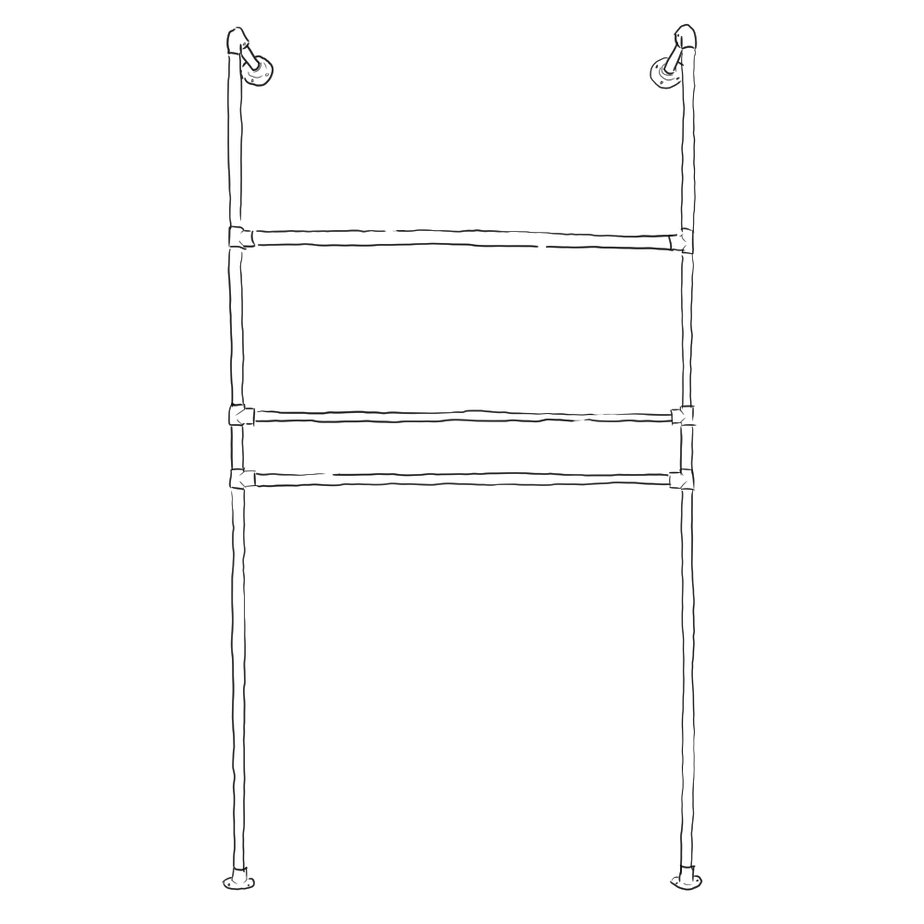

Build Your Eco-Friendly Solutions with Select FIT New Zealand

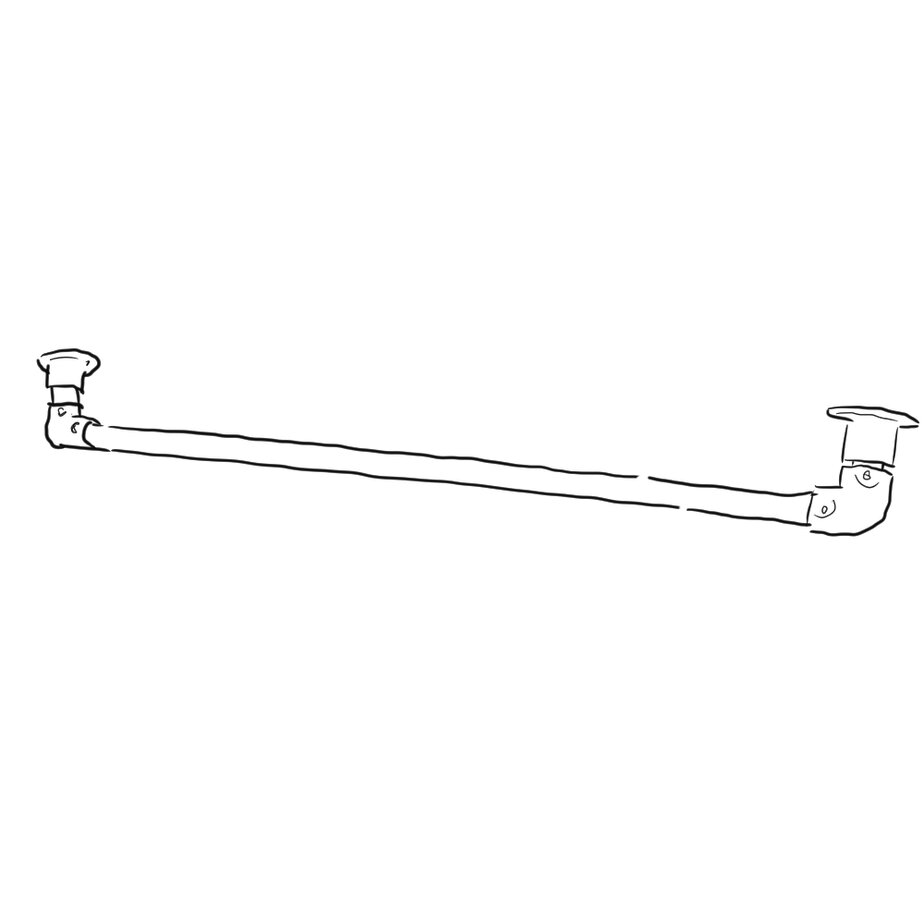

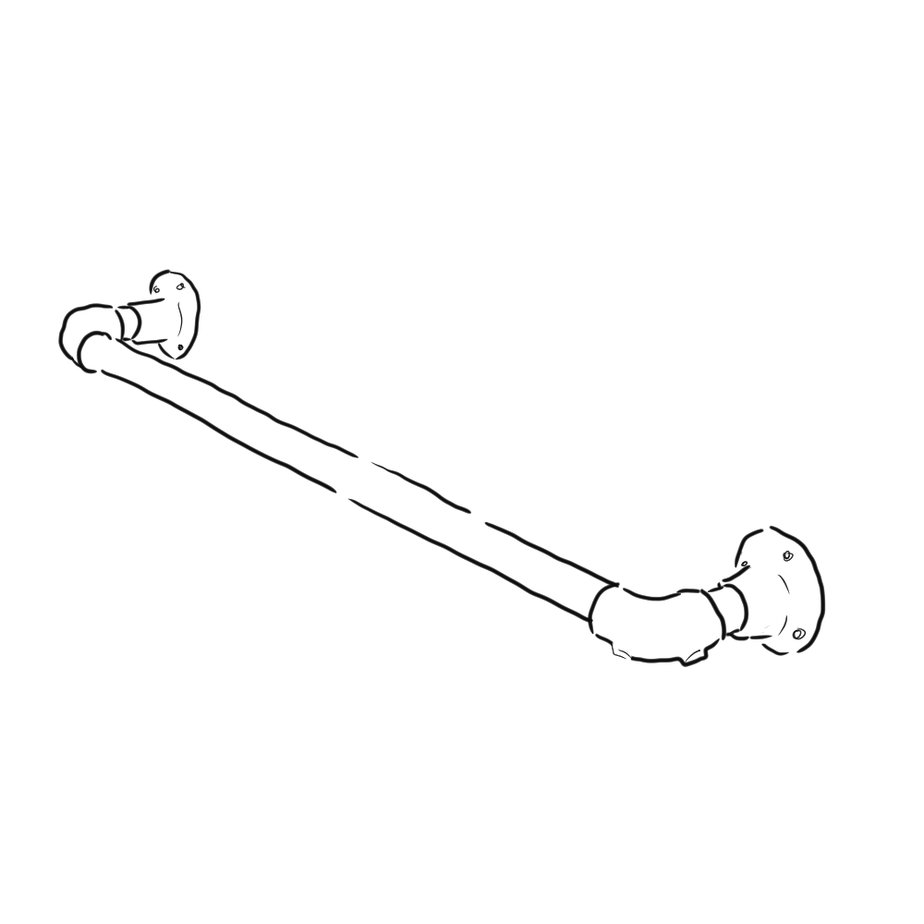

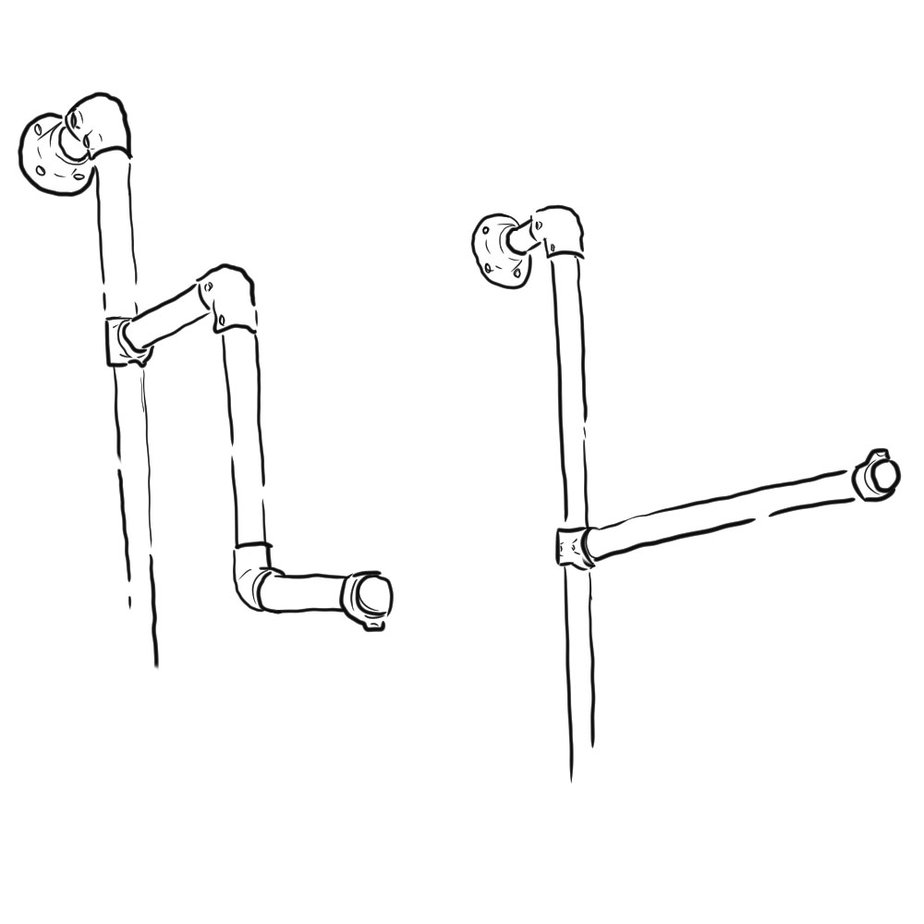

Are you looking for a way to build your own eco-friendly design projects? Whether you want to create a green house, a solar panel, or a compost bin, you can do it with the help of Kee Klamp fittings.

These fittings are versatile and easy to use components that allow you to connect tubes and pipes of different sizes and shapes. You can use them to create sturdy and durable structures that can withstand various weather conditions and loads. The fittings are also reusable and recyclable, which means you can reduce your environmental impact and save money.

At selectfit.co.nz, you can find a wide range of pipe fittings that are made of high quality steel and have a galvanised finish that prevents rust and corrosion. They are also compliant with EN 14122: 2016 & OSHA requirements and CE marked for assured and safe operation.

To use pipe fittings, you don’t need any special tools or skills. You just need a hex key and a pipe cutter to tighten the fittings and cut the tubes to the desired length. You can also check out our blogs to get some inspiration and tips on how to build your own eco-friendly design projects.

Related Blog Posts

If you are interested in building your own greenhouse, you may want to check out some of the best greenhouse blogs we have on our website.

Greenhouse staging for any kind of space

Greenhouse staging for any kind of space The article is...

Read MoreDIY easy-to-build greenhouse structure

DIY easy to build greenhouse structure The article is used...

Read More