DIY Industrial Bed With Headboard And Footboard

DIY Camden bed frame is easy to put together, super sturdy and looks fantastic. Two people are required to build this one, and it can be done using just an Allen key.

Materials: Galvanised steel tube and Kee Klamp fittings

Finish: Galvanised steel (not coloured)

The article is used with permission from Simplified Building UK

https://simplifiedbuilding.co.uk/projects/diy-industrial-bed-with-headboard-and-footboard

A king size bed you can put together in less than an hour.

Like the idea of an industrial look for your bedroom? This DIY bed frame is a great way to achieve a minimalist and industrial look!

King size bed dimensions:

- Length: 200 cm

- Width: 150 cm

- Headboard height: 120 cm

- Footboard height: 80 cm

For this project you’ll need

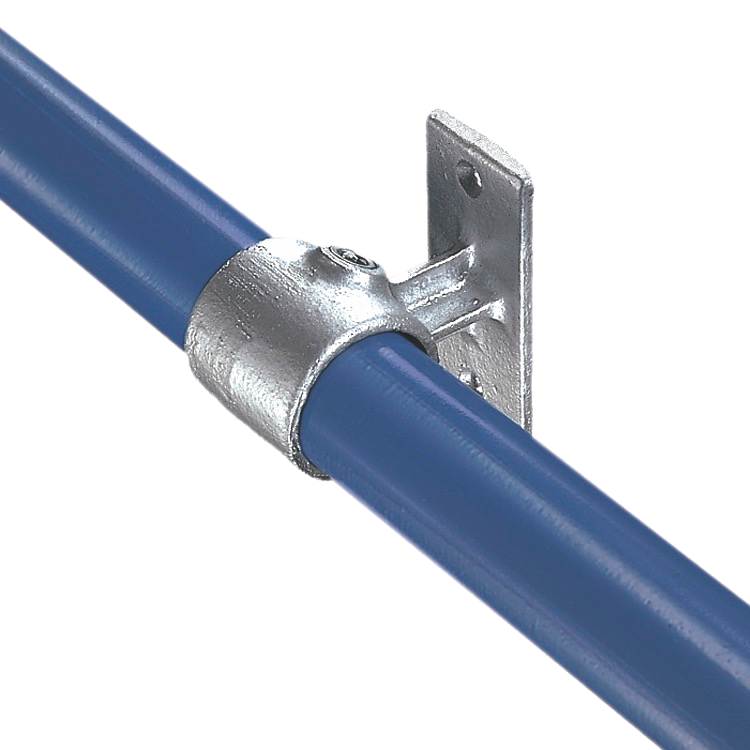

- Kee Klamp fittings, in size 6, made of galvanised steel

- Galvanised steel tube, in size 6

- Bed slats (need to be purchased separately)

Start assembling the footboard first, using 10-6 and 15-6 fittings to connect the tubes.

When doing this, make sure that you insert the 10-6 that will hold the tube for your bed slats support.

Use a measuring tape to make sure that the smaller tube sections of the footboard are placed at an equal distance from each other.

Then attach the flanges (61-6) to the bed legs.

Once the footboard is put together, start building the headboard using the same technique, making sure you remember to add the 10-6 fittings that will later hold the slats support:

The next step is to connect the footboard and the headboard using the longer pieces of tube. Start adding the tube from one side, working your way through to the other side.

Finally, add the bed slats (purchased at a local DIY store), add the mattress, and your bed is ready!

Alternatively, here are a few fittings you can request separately to help you out: